QEII BRIDGE

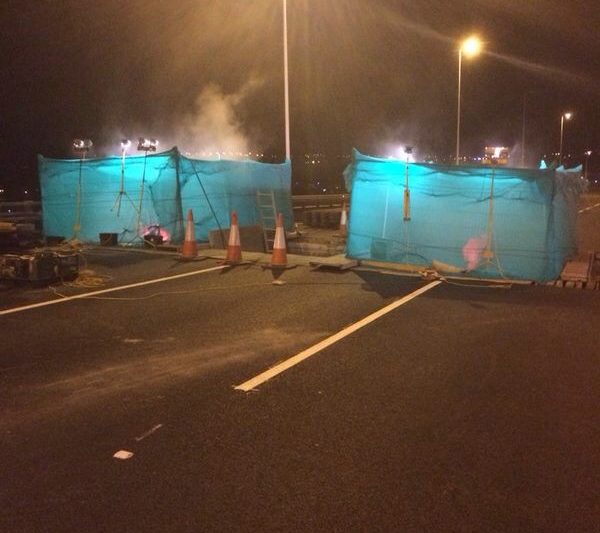

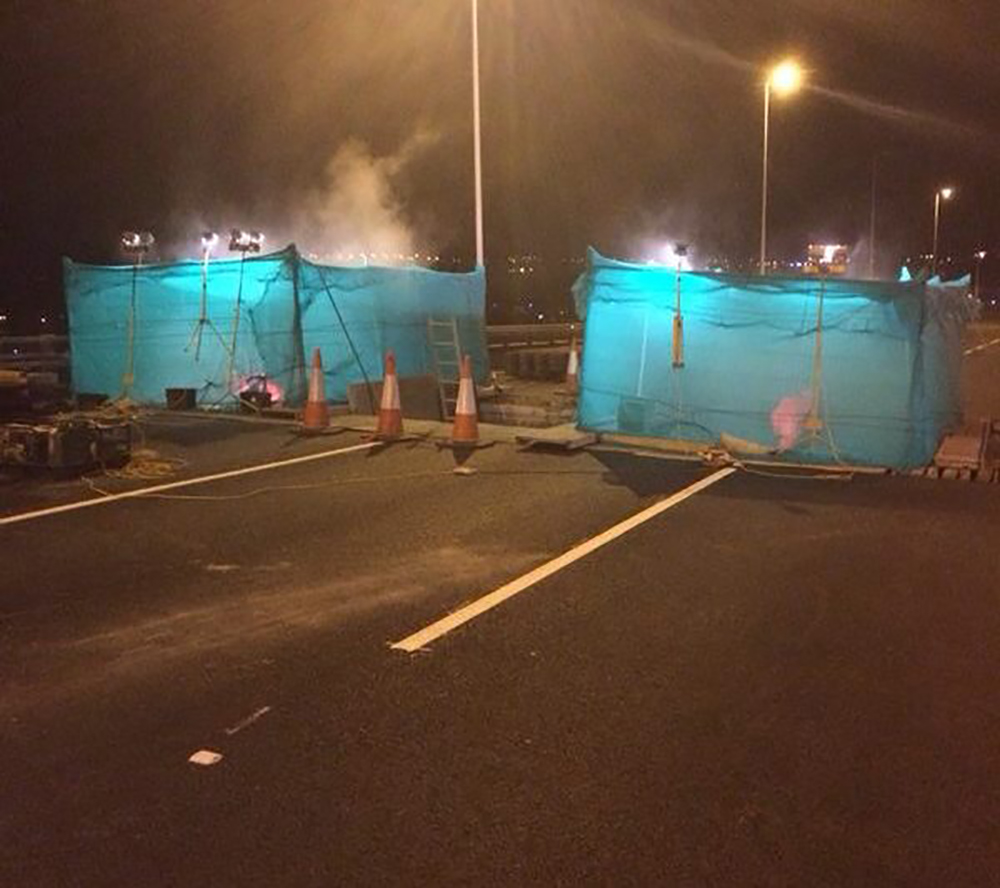

The hydrodemolition works at the QEII Bridge were amongst the most difficult that we have carried out in recent years. The project required the shelf at the top of the piers and abutments to be removed. The works were so high that for some phases a lift was required to get up to the work area from the ground level below. The work area was very well contained to prevent debris escape but this made for extremely hot working conditions and the operators had to rotate roles more frequently than usual. For each phase we started on days until we couldn’t remove any more concrete due to the structural constraints of the bridge and the tight access available. At this point the works switched to nights where it became critical to work in the most efficient manner possible. Each night we had approximately 6hrs to setup containment for two teams, hydro-demolish as much as of the shelf as possible and then pack everything away. Despite the difficulties whilst working during the day and the time constraints at night, we still managed to achieve an average breakout of 0.5m3 / shift / crew. This volume removed per shift was almost double what was predicted by our competitors at tender stage. The works were completed in a shorter period and for a more competitive price than our competitors could manage.

Water Supply

The most straight forward part of the works was organising the water supply for the jetting units. There were hydrants available for both the north & south phases on either side of the Thames. The only difference being that the north was in the Essex & Suffolk Water region whilst the South was in the Thames Water region. Sabre organised the licensed standpipes and ran out inlet hose from the hydrants to the works taking the responsibility away from the client.

Waste Water Treatment

As with the water supply, the sewers for each phase were controlled by two separate companies. However, with regard to the disposal, two different methods were employed. On the north phase we had access to a foul sewer for the discharge of the run-off water. This meant that the water simply had to be filtered to reduce the suspended solids. Sabre dealt with Essex & Suffolk Water to arrange the temporary discharge consent and provided a Siltbuster HB10 Unit with all necessary pumps and hoses to remove the water from the sump area, treat and discharge. On the south side there were no foul sewers available. This meant that the water had to be treated to a higher standard before being discharged to a French drain. We therefore provided one of our Siltbuster HD Units for pH correction & filtration of the run-off water. Our Team Leader on site monitored the unit daily to ensure the pH correction was working correctly and that the water discharged was of an acceptable standard at all times.

WORK WITH US

We are always happy to make new connections,

so if you wish to work with us or simply want more information regarding Hydro Demolition, Surface Preparation and Tank Cleaning